Specialized Resistors

Specialized resistors are resistors that are made for a particular purpose or usage, apart from the standard resistors used in electronic devices. These resistors are made to satisfy particular needs, such extreme precision. Stability in response to temperature variations the capacity to withstand high power or resistance to outside influences like vibration or dampness.

Basic Types of Resistors

An essential part of electrical circuits are resistors. A summary of the fundamental kinds of resistance to electric current flow is as follows:

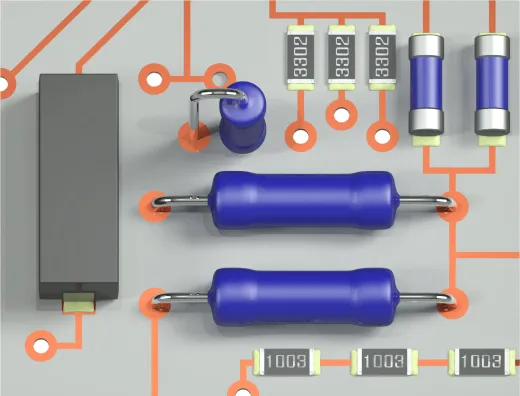

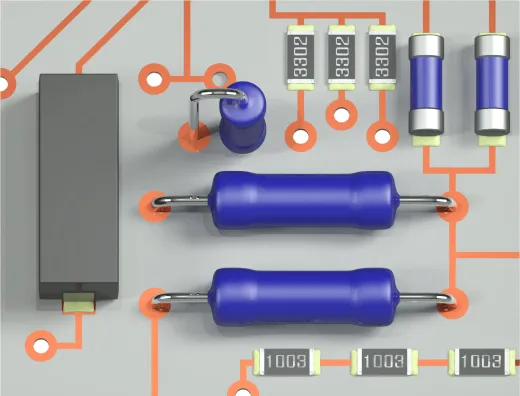

1. Fixed Resistors:

– Carbon Composition: Composed of a carbon and ceramic blend. They are widely utilized in general circuits and are reasonably priced.

– Metal Film: Made by depositing a thin metal film on a ceramic rod. They offer better stability and precision compared to carbon composition resistors.

– Wire-wound: Created by encircling a ceramic core with a metal wire (such as nichrome). They offer very precise values and high power ratings, suitable for high-power applications.

2. Variable Resistors:

– Rheostats: A resistor that can be adjusted, featuring two terminals and a sliding or revolving contact that modifies resistance.

– Potentiometers: Like that of a rheostat. possesses three connectors, nevertheless. where a variable voltage divider is acted upon by the third terminal.

Applications in Basic Circuit Designs:

– Current Limiting: Used to protect the component by limiting the amount of current that passes through the circuit.

– Voltage Division: Utilized to set the reference voltage or step down the voltage in voltage divider circuits.

– Signal Conditioning: Signal level adjustments for amplifiers and other electronic equipment.

– Timing Circuits: Setting time constants in RC (resistor-capacitor) circuits for timing functions.

Specialized Resistors

Specialized resistors are designed to meet specific requirements beyond those of standard resistors. Here’s an overview of some common types:

1. Precision Resistors:

– Characteristics: Tolerances for precision resistors are quite close. They typically range from 0.01% to 1%, indicating that the resistance value in practice is rather near to the given number.

– Uses: Especially significant in applications like precision measuring tools where accuracy is essential. devices used in the medical and audio fields where distortion and noise reduction are crucial.

2. High-Power Resistors:

– Characteristics: Large power dissipation is possible with these resistors without sacrificing performance. They are often physically larger with robust construction.

– Uses: Power supplies employ high power resistors. applications such as braking systems, motor control circuits, and any other application requiring the safe dissipation of significant electrical energy.

3. Surface Mount Resistors (SMD):

– Characteristics: Small and suited for automatic placement on printed circuit boards (PCBs), SMD resistors are lightweight. Various sizes (e.g., 0402, 0603, 0805) are available to signify size.

– Uses: Because SMD resistors are tiny and work well with high-density PCBs, they are commonly employed in modern electronics. Computers, cellphones, and electrical equipment all contain them. electronics found in cars.

Advanced Applications

1 Precision Resistors

Use in Precise Measurement Circuits

Precision resistors are integral to circuits where accuracy and stability are crucial. Their low tolerance ensures minimal deviation from their nominal resistance, which is essential for maintaining the accuracy of the overall circuit. This makes them suitable for:

– Bridge Circuits: To quantify minute variations in resistance, one can employ Wheatstone bridges.

– Analog-to-Digital Converters (ADCs): Ensures precise translation of analog impulses into digital information.

– Feedback Networks: In operational amplifiers where precise gain control is necessary.

Examples in Medical Equipment and Scientific Instruments

– Medical Equipment: Precision resistors are essential for precise signal processing and measurement in devices like dosage pumps, blood pressure monitors, and electrocardiogram machines (ECG machines).

– Scientific Instruments: Spectrophotometers, oscilloscopes, and precision balances are a few examples of the laboratory instruments that use precision resistors. This is the point at which consistent and accurate measurement is crucial.

2 High-Power Resistors

Applications in Power Electronics and Industrial Equipment

In situations where significant electrical power dissipation is necessary, high-power resistors are crucial. Common applications include:

– Power Supplies: Used for load testing and in dummy loads.

– Motor Control Circuits: Gives electric motors dynamic braking and current limitation.

– Industrial Equipment: Heavy machinery such as welding machines and heaters use high-power resistors. equipped to distribute and manage high energy loads.

Thermal Management and Reliability Considerations

– Heat Dissipation: High-power resistors must effectively dissipate heat to prevent failure. This often involves the use of heat sinks or mounting the resistors on heat-dissipating substrates.

– Material Choice: Usually, they are composed of heat-resistant materials like metal oxide or wire wrap.

– Reliability: Long-term reliability requires taking environmental stress and thermal cycling into account, among other things. Performance and longevity may be impacted by this.

3 Surface Mount Resistors

Advantages in Miniaturization and High-Density Circuit Boards

Surface mount resistors offer significant benefits for modern electronic designs:

– Compact Size: They allow more components to be put in a limited area since they take up less space on the PCB.

– Automated Assembly: Pick and place machines that operate automatically can work with SMD resistors. It lowers expenses and improves manufacturing efficiency.

– Improved Performance: Their diminutive dimensions may result in less parasitic capacitance and inductance. beneficial for applications involving high frequencies.

Applications in Consumer Electronics and Telecommunications

– Consumer Electronics: Widely utilized in devices with limited space, such as wearables, computers, tablets, and cellphones.

– Telecommunications: Necessary for network equipment, such as switches, routers, and communication devices. For sophisticated functions, high-density circuits are needed.

Emerging Trends: Development of Smart Resistors

A recent development in electronic components are smart resistors. These resistors have the ability to modify their resistance in response to outside stimuli like temperature, voltage, and other environmental elements. Many sectors may be significantly impacted by the development of smart resistors. through the development of more flexible and effective electrical circuits. This may result in improved energy administration. enhanced detection precision and enhanced electronic system performance in general. Smart resistors can have a significant impact in a variety of fields, including automobile electronics. Advanced processing and a system of renewable energy.

Challenges and Considerations

Cost Implications of Specialized Resistors

As resistor technology develops, the price of specialized resistors may therefore start to matter. Additional unique resistors with extremely accurate temperature adjustment Generally speaking, they are of higher grade than ordinary resistors. Rising prices might hinder a broad adoption. This is especially true for appliances, since they need to be economical. Manufacturers must weigh the advantages and disadvantages of advanced resistor technology in order to keep prices competitive without compromising the quality of their products.

Environmental Considerations

Environmental factors are becoming more and more significant in the electronics sector. For instance, only electronic components may employ hazardous chemicals according to the RoHS Directive. Manufacturers who sell their goods abroad are required to abide by environmental regulations such as RoHS. To avoid using hazardous materials like lead, mercury, and cadmium in the process of making resistors, certain regulations must be followed. This covers the application of eco-friendly production techniques and substitute materials. The management of end-of-life electronic component disposal and recycling is crucial to preserve resistor performance and dependability.