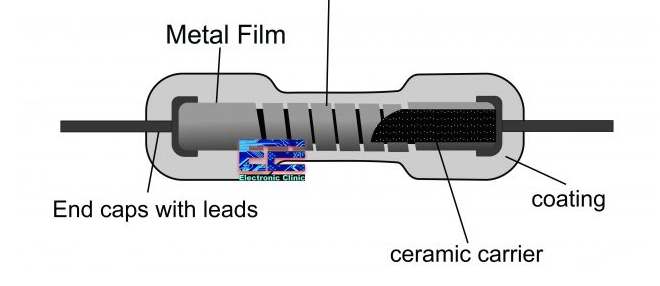

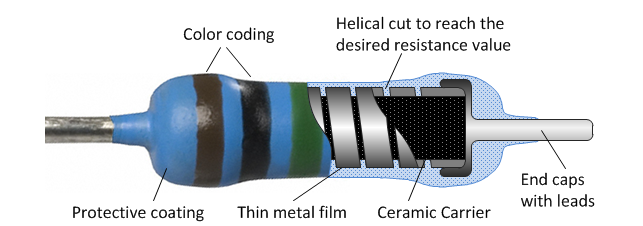

Metal film resistors, distinguished by their axial leaded configuration, employ a thin metal film deposited into a ceramic rod as the resistive element within the electronic component.

Presently, metal film resistors reign as the most extensively utilized type in this category, sometimes posing challenges to procure earlier resistor types. This resistor type outshines metal oxide film resistors and predecessors like carbon film and carbon composition resistors, delivering superior performance across various metrics.

While the term “metal film resistor” commonly denotes axial leaded components, the same technology extends to thin film surface mount chip resistors. Consequently, metal film technology stands as the most prevalent in the realm of resistors.

Performance-wise, the metal film resistor excels, offering heightened stability, accuracy, reliability, and notably reduced noise generation compared to alternative types such as carbon composition, carbon film, and even metal oxide film resistors available in the market.

Metal Film Resistor Definition

Metal film resistors feature a slender metal layer serving as the resistive component on a non-conductive base. These resistors stand as one of the prevalent axial resistor variants. Carbon film, thick film, and thin film resistors also fall under the film-type resistor category. The term “metal film resistor” commonly denotes a cylindrical axial resistor in most literature. Nevertheless, thin film chip resistors adhere to the same manufacturing principle for the metallic layer. While metal film resistors may resemble carbon film resistors in appearance, their attributes pertaining to stability, accuracy, and reliability notably surpass the latter.

The metal film resistor is crafted by applying a fine layer of metal onto a ceramic substrate, aligning with its name. Functioning akin to resistance wire, the precise control over the thickness, width, and length enables the production of high-tolerance metal film resistors.

Moreover, by pre-aging the metal and implementing protective measures, these resistors maintain excellent long-term stability, safeguarding against degradation over time.

Due to their attributes, metal film resistors have surged in popularity as the preferred option for leaded axial resistors, leading to their widespread use in significant quantities.

Manufacturing and Construction of Metal Film Resistors

The metal film resistor is crafted through a process involving the vacuum deposition of a metal layer onto a high-purity ceramic cylindrical rod.

Typically, the stability of the resistor value increases with a thicker deposition of the metal film. The material’s thickness significantly influences the resistance, wherein thicker material equates to lower resistance. However, factors like the material’s resistivity and the width of the subsequent helical cut in the process play a crucial role.

Normally, film thicknesses ranging between 50 and 250nm are employed for enhanced long-term stability. Various techniques, with sputtering being a common one, are utilized for this purpose. Nickel chromium (NiCr) is frequently the deposited metal, although specialized applications might call for other metals like gold with platinum or tantalum nitride.

Following the deposition of the film, a metal end cap is pressed onto the deposited metal, establishing contact with the resistive film and housing the integrated leads. These metal caps establish connectivity with the resistive element and are linked to the leads exiting the overall structure, facilitating electrical connections.

Following deposition, the subsequent manufacturing step involves adjusting the resistance value to meet specifications. This commonly involves utilizing lasers to create a helical pattern in the metal film. This elongates the metal element and narrows the current-carrying track, maintaining the deposited material thickness within the optimal range for long-term stability.

Laser trimming ensures precise adjustments, enabling metal film resistors to achieve remarkably close tolerances. Variants with tolerances of 0.1%, 0.25%, 0.5%, 1%, and 2% are available, with 1% and 2% being the most prevalent. Their tight tolerances facilitate consistent repeatability across circuits from one unit to another.

Additionally, metal film resistors uphold a favorable temperature coefficient of resistance, typically falling between 50 and 100 ppm/°K.

The final stages of manufacturing entail applying a protective coating and markings. Typically, a resin-based protective coating is applied in multiple layers, each baked individually. Subsequently, marking rings are added to denote the metal film resistor’s value and other pertinent characteristics.

Surface mount resistors share the basic technology of metal film but undergo a distinct manufacturing process due to differing mechanical considerations.

Applications of Metal Film Resistor

Metal film leaded resistors currently stand as the primary standard for low-power general-purpose resistors among leaded variants. Their widespread usage across applications owes to factors such as cost-effectiveness, reliability, and the availability of tight tolerance options, making them nearly ubiquitous in this resistor category.

While surface mount resistors see higher usage due to advancements in volume manufacturing techniques, metal film resistors remain the go-to choice when leaded electronic components are required.

With their ability to offer high tolerance, long-term stability, favorable temperature coefficient of resistance, and reliable voltage stability, these resistors instill confidence in their suitability for most applications.

Their operational efficiency thrives when operated below maximum ratings, a common practice in design, often maintained at around 50 to 60% of their maximum rating to ensure optimal performance.

However, due to their construction, metal film resistors aren’t ideal for applications prone to surge transients. Carbon composition resistors excel in such scenarios, handling transients more effectively.

Additionally, the helical cut used to adjust resistance might introduce slight inductance, potentially affecting performance, particularly in the microwave frequency range. Surface mount resistors are often preferred for such applications.

Another advantage of metal film resistors lies in their minimal noise generation attributed to their construction and technology.

Reliability of Metal Film Resistor

To ensure optimal reliability, metal film resistors are typically operated within the range of 20% to 80% of their designated power rating. Enhancing reliability often involves a 50% derating practice. Yet, in certain niche scenarios such as humid environments, reliability might diminish, even when these resistors operate below 20% of their power rating. Contrasted with wirewound or carbon composition resistors, metal film resistors are more susceptible to damage from voltage surges and excessive power loads.

Common specifications for metal film resistors

Metal film resistors adhere to many of the same parameters utilized for other resistor types. These include value, accuracy, power dissipation, generated noise, and various others that apply universally to metal film resistors. Currently, metal film resistors dominate as the most commonly used axial leaded resistors, surpassing other types, including metal oxide film resistors. Offering superior performance in most instances at a lower cost compared to alternative types, they’ve been widely embraced, becoming nearly ubiquitous except for specific applications.

These resistors are available in various power dissipation ratings like quarter-watt, half-watt, and one-watt formats, among others. Different manufacturers might present varying dissipation levels, necessitating reference to specific specifications.

Visually distinguishing between metal film resistors and their close counterpart, the metal oxide film, is challenging if not impossible. Fortunately, the performance of both types is generally akin, rendering the visual distinction inconsequential in most scenarios. Presently, the majority of leaded resistors in use are of the metal film variety rather than metal oxide film.