What is the Tilt Sensors?

A tilt sensor, commonly referred to as a tilt switch, serves to gauge an object’s tilt across various axes concerning an absolute level plane. These devices, compact and small in size, emerge as a practical choice for applications reliant on detecting orientation or inclination, such as safety systems in construction or agricultural machinery. At Level Developments, our tilt switches, complementing our extensive line of inclinometers and inclinometer sensors, leverage highly precise sensors for operation, offering an edge over alternatives like mercury switches or rolling ball mechanisms.

The functionality of tilt sensors revolves around detecting alterations in angle from a predetermined “zero” position. Configured with specific maximum and minimum thresholds, these sensors ensure that the application operates within safe parameters based on its unique requirements. Should the tilt surpass these set thresholds in either direction, the switch triggers a relay, initiating the closure of the switch. This action prompts an external device—such as an alarm or warning light—to signal unsafe or non-operational conditions.

Given the expansive array of applications, exploring tilt sensors involves considering specific specifications crucial for selecting the right device.

What is the Tilt Switches?

Switching Range: These encompass the Switching Range, delineating the angle span within which the device functions, triggering the switch upon surpassing the tilt threshold (trip angle). Our devices offer varied tilt thresholds that users can manually adjust on the PCB, ensuring the desired trip angle for any application.

Switching Accuracy: Switching accuracy is pivotal, dictating the proximity of the measured angle to the actual angle. Typically, a reduction in the switching range of a tilt sensor corresponds to heightened accuracy.

Filter Frequency:Furthermore, due to numerous tilt switch applications in environments prone to high vibration, employing both analog and digital filtering becomes essential. These filters attenuate noise and vibrations, preserving the accuracy and precision of readings by limiting interference. Our tilt switches present filter options at frequencies of 0.5Hz, 1Hz, and 2Hz, effectively mitigating disruptive noise.

The number of axes plays a crucial role as various applications demand measurements across different axes. Our product line accommodates single, dual, and omni-directional axis configurations. The dual-axis variant enables independent adjustment of tilt thresholds for the X and Y axes, whereas the single-axis version exclusively monitors the X axis. Meanwhile, the omni-directional version consolidates measurements from both axes to compute the resultant tilt angle, triggering the switch upon surpassing the threshold angle in any direction.

Considering cost and material becomes imperative when exploring tilt switches. At Level Developments, our tilt switches are available in either durable ABS plastic or robust anodized aluminum housing, catering to diverse applications. This range of material options coupled with varied switching ranges ensures a cost-effective solution for every application, including OEM solutions tailored to specific customer requirements.

Other Types of Tilt Switches

Many tilt switches today are labeled “non-mercury” owing to historical and current operations utilizing mercury to open and close circuits. Traditionally, a small amount of mercury facilitated the switch’s functioning by establishing contact with an electrode upon tilting beyond a certain angle.

Tilt ball switches have emerged as a prevalent alternative to mercury-based ones, employing a metallic ball to trigger circuit connectivity based on the angle and direction of tilt. This shift is primarily due to safety concerns and the non-toxic nature of ball switches. However, their use is limited in high-vibration settings due to a lack of effective noise filtering.

In contrast, MEMS sensor switches present numerous advantages over these alternatives. Renowned for their precision, reliability, and adjustable trip angle threshold, MEMS switches offer noise filtering capabilities ideal for heavy-duty applications. Moreover, their absence of moving parts reduces maintenance needs, ensuring an extended lifespan. MEMS technology, known for these benefits, is widely applied in our inclinometers and inclinometer sensors.

Advantages and disadvantages of tilt switches

Advantages:

Simple and easy to use

Low cost

Can be used in a variety of applications

Can be used in harsh environments

Disadvantages:

Limited functionality

Limited accuracy

Limited lifespan

Can be affected by external factors such as vibration and shock

Advantages and disadvantages of tilt switches

|

Feature |

Tilt Switches |

Tilt Sensors |

|---|---|---|

|

Definition |

Electromechanical switches that become ON or OFF based on the degree of tilt or inclination |

Electronic devices that measure the tilt of an object in multiple axes with reference to an absolute level plane |

|

Working Principle |

SPST type with either normally open or normally closed |

Single axis/single output, dual axis/dual output, and dual axis/single output |

|

Types |

Mercury-based, ball-type, and others |

MEMS-based, electrolytic, and others |

|

Advantages |

Simple and easy to use, low cost, can be used in a variety of applications, can be used in harsh environments |

High accuracy, high High accuracy, high sensitivity, can be used in a wide range of applications, can be used in harsh environments |

|

Disadvantages |

Limited functionality, limited accuracy, limited lifespan, can be affected by external factors such as vibration and shock |

Expensive, complex, require calibration, can be affected by external factors such as temperature and humidity |

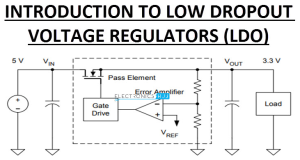

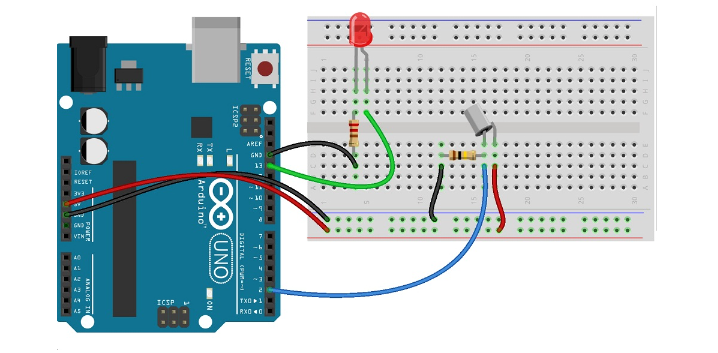

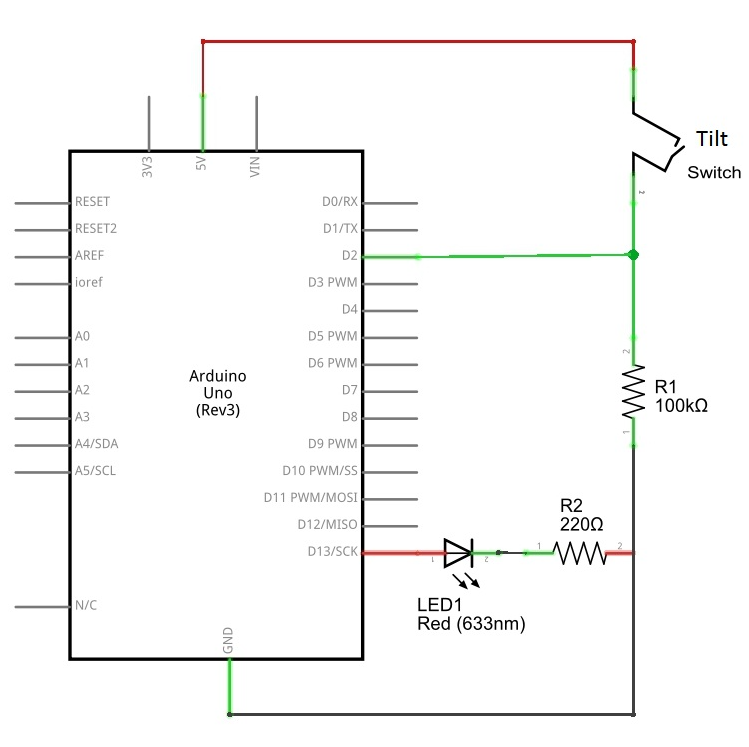

Circuit diagram

Application: Tilt Switches vs Tilt Sensors

Tilt switches are simple and easy to use, low cost, and can be used in a variety of applications. They can be use d in harsh environments and are available in different types such as mercury-based, ball-type, and others 1. Tilt sensors, on the other hand, are highly accurate, have high sensitivity, and can be used in a wide range of applications. They can also be used in harsh environments 2. The accuracy of tilt sensors can be up to ±0.25° with a resolution of up to ±0.01° 2. Tilt sensors are based on MEMS technology and can be single or dual-axis with either digital or analog output signals and multiple mounting options 2.

The choice between tilt switches and tilt sensors depends on the specific application requirements. Tilt switches are suitable for applications that require simple and low-cost solutions, while tilt sensors are ideal for applications that require high accuracy and sensitivity.

Conclusion

Here is a summary of the differences between tilt switches and tilt sensors:

Tilt switches are electromechanical switches that become ON or OFF based on the degree of tilt or inclination. They are simple and easy to use, low cost, and can be used in a variety of applications. Tilt switches can be used in harsh environments and are available in different types such as mercury-based, ball-type, and others .

Tilt sensors, on the other hand, are electronic devices that measure the tilt of an object in multiple axes with reference to an absolute level plane. They are based on MEMS technology and can be single or dual-axis with either digital or analog output signals and multiple mounting options. Tilt sensors are highly accurate, have high sensitivity, and can be used in a wide range of applications. They can also be used in harsh environments 2. The accuracy of tilt sensors can be up to ±0.25° with a resolution of up to ±0.01° .