Here is an outline of the article:

A Time Delay Relay: What Is It?

Structure of time delay relay

How Time Delay Relays work

Applications of timing relays

Types of Time Delay Relay

Time delay relay applications in industrial automation

Conclusion of the time day relay

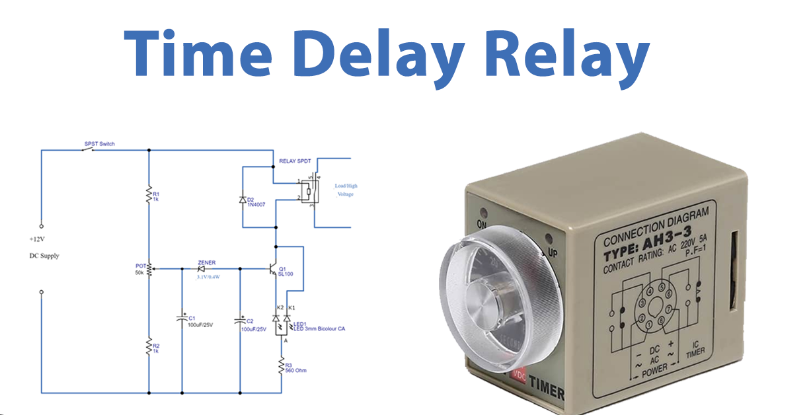

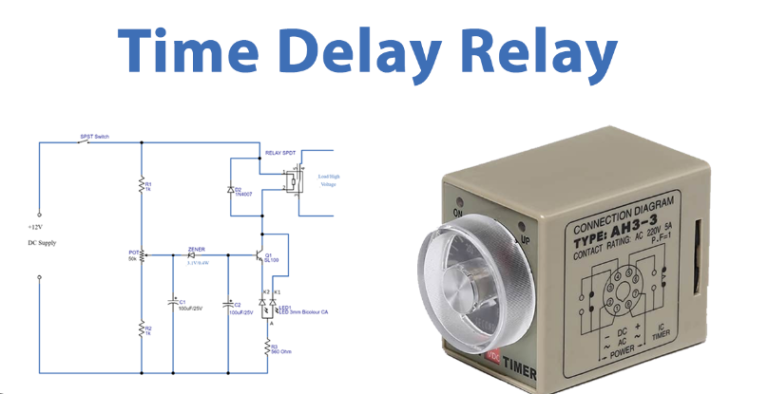

A Time Delay Relay: What Is It?

Relays with an integrated time delay function are known as time delay relays. This means that after being energized, the relay will wait a predetermined amount of time before turning on. Applications like industrial automation or security systems that need to wait for the relay to activate can benefit from this.

Time delay relays come in a wide variety, each with special features and functionalities. While some relays have time delays that can be adjusted, some have fixed time delays that are not modifiable. Furthermore, although some relays can select from a variety of time ranges, some are only available in one.

Structure of time delay relay

Time delay relay is a kind of control appliance that realizes delay control based on electromagnetic principle or mechanical principle. Its types include electromagnetic time delay relays; trigger time relays; thermal time delay relays; hybrid time delay relays; and solid time relays. Among them, the electromagnetic time delay relay is composed of an iron core, a coil, an armature, a contact spring, etc.

How Time Delay Relays work

As long as the voltage of the coil is applied to the coil, a current will flow in the coil, thereby producing an electromagnetic effect, and the armature will produce a current in the coil. Under the action of electromagnetic force, the pulling force of the return spring is attracted to the iron core, thereby driving the movable contact and the static contact (normally open contact) of the armature to close. When the coil is powered off, the attraction of the electromagnetic force also disappears, and the armature will return under the reaction force of the spring, causing the moving contact and the static contact (normally closed contact) to attract. By attracting and releasing, the purpose of conducting and cutting off in the circuit is achieved.

Applications of timing relays

Many industrial and commercial applications frequently use timing relays. Buildings, machinery, water segments, HVAC systems, and other applications are a few examples of popular applications.

Machine Control

They are frequently employed to offer cyclic machinery switching in machine control applications. This may lessen the chance of equipment sticking or getting harmed.

Lighting Control

In greenhouses or production facilities, timing relays can be used to delay the switching of many rows of lamps. By keeping lights off when not in use, this can contribute to energy conservation.

Water segments

Timing relays are frequently used in the water segment for pump controllers and irrigation systems.

HVAC Control

It is applicable to centralized water systems and fan control in HVAC systems. Building comfort and energy conservation can both benefit from this.

Alarm Triggering

Alarms can be set to sound after a predetermined period of time has passed using timing relays. Applications involving security or monitoring may find this helpful.

These are but a handful of applications for timing relays. These adaptable gadgets have a plethora of additional possible uses.

Types of Time Delay Relay

ON-Delay Timers

One kind of time delay relay used to regulate circuit activation is the ON-delay timer, which delays the start of current flow. In situations where it’s crucial to make sure a circuit isn’t turned on until after a predetermined period of time has passed, ON-delay timers are frequently utilized. This can help avoid unintentional circuit activation or give a system time to stabilize before turning it on.

OFF-Delay Timers

One kind of time delay relay that opens or closes the circuit when power is cut off is the OFF-delay timer. The load is de-energized once the predetermined time delay has passed, at which point the contacts will revert to their original position. “Delay on break” timers are another term for OFF-delay timers.

During timing, the time delay would reset if you closed the control switch again. However, most OFF-delay timers reset automatically when power is disconnected, but some models allow for manual resetting.

One timing

A time delay relay called a one-shot timer is used to start a circuit after a predetermined period of time. They go by the names single shot timers, single pulse timers, and single shot interval timers as well. Power is required to start one-shot timers. The contacts shift positions as soon as power is supplied.

They occupy this new site for a predetermined amount of time before moving back to their former location. When the previous cycle ends and the switch that controls it is turned off, the timer resets itself. In industrial settings, one-shot timers are frequently employed to control machinery’s start/stop buttons.

Interval Timers

A time delay relay called an interval timer is used to regulate how long an electrical load is powered on. They are also known as delay on energization with instantaneous transfer timers, bypass timing timers, interval delay timers, and pulse shaping timers.

These timers function by holding off on applying power to an electrical load until a predetermined amount of time has passed. The electricity is turned on after the timer goes off and stays on until it does. At this point, the load loses power and doesn’t get it back until power is applied again.

Recycle Timers

One kind of time delay relay used to regulate the on and off cycling of a load is the recycle timer. They go by the names duty cycling or cycle timers as well. By periodically turning a load on and off, these timers help save energy. They can be applied to produce a flashing effect as well. Recycle timers can be single- or multi-functioning gadgets.

Time delay relay applications in industrial automation

Time delay relays have a variety of important applications in industrial automation, where they provide a time delay function that helps achieve precise control and coordination of automation systems. Here are some of the main applications of time delay relays in industrial automation:

Starting and Stopping Equipment: Time delay relays are used in automation systems to delay starting or stopping equipment to ensure that the equipment operates at the correct time. For example, they can be used to start electric motors, conveyor belts, pumps or other production equipment to coordinate production processes.

Prevent motor overload: Time delay relays can be used to monitor the current of the motor and cut off the power supply when the motor is overloaded to prevent equipment damage or failure. This helps maintain the safety and reliability of your equipment.

Coordinate lights and lighting systems: In industrial settings, time delay relays can be used to coordinate the operation of lighting systems. They can turn lights on and off one by one or group by group to improve energy efficiency and ensure lighting adapts to production needs.

Cooling system control: In industrial equipment, time delay relays can be used to control the start and stop of the cooling system. This helps maintain the proper operating temperature of equipment and machinery, thereby increasing their longevity and efficiency.

Delayed Alarm and Fault Detection: Time delay relays can be used to provide delayed alarms when a problem or fault is detected. This helps maintenance personnel take timely action to fix the problem.

Production line synchronization: In automated production lines, time delay relays can be used to ensure the synchronized operation of different equipment and processes. They coordinate operations between different steps to increase production efficiency.

Energy Saving Control: Time delay relays can be used to save energy, for example, they can shut down equipment to reduce energy consumption when it is temporarily not required to operate.

Safety door control: Time delay relays are used to control safety doors in factories to ensure that workers do not accidentally enter dangerous areas when the machine is running.

Cycle control: In some production processes, periodic operations are required, and time delay relays can achieve cycle control, for example, by introducing a time delay between cycles to achieve periodic cleaning or processing.

Conclusion of the time day relay

Time delay relays regulate the activation of circuits after a predetermined period of time. Different time delay relays exist, and each has a distinct purpose. Time delay relays are frequently used to postpone the activation of a circuit, control the on and off cycling of a load, and regulate the start and stop of machinery.