Understanding Dip Switches: A Comprehensive Guide to Configuration and Usage

What are Dual In-line Package(Dip) Switches?

Dip switches, short for Dual In-line Package switches, are miniature switches mounted on a printed circuit board (PCB). They are designed to enable the manual configuration of electronic devices. Initially, they were used in computers and other electronics to set system configurations, allowing users to customize hardware settings without modifying the device’s wiring or code.

How Dip Switches Work

Basic Functionality

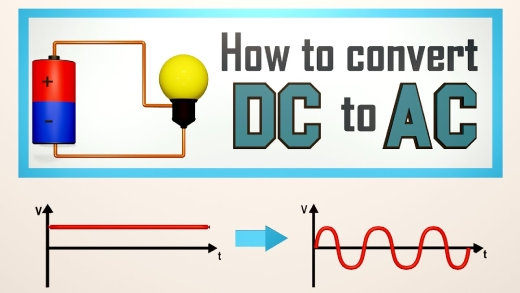

A basic idea underlies the operation of dip switches. To customize how the electrical equipment operates, you can manually adjust its dual (on/off) setting options. The “on” and “off” positions of each switch in the dip switch package correspond to high and low power states, respectively. This enables the configuration of a large number of settings and options by combining the locations of many switches.

Internal Mechanisms

The internal mechanism of a dip switch is relatively simple yet effective. A tiny actuator is connected or removed from a pair of conductive terminals that make up each switch in the pack. The actuator closes the space between the terminals to permit electric current to flow through when the switch is in the “on” position. On the other hand, the actuator moves away while the switch is in the “closed” position. It stops the current from flowing and breaks the circuit.

Common Configurations

Dip switches are frequently employed in a variety of settings. For instance, there are 16 possible permutations (2^4) for setting each of the four switches in a basic dip pack to “on” or “off,” allowing for the creation of various configurations. It is possible to set several operation modes with these combinations. In more complex systems, dip switches can be combined with other components such as jumpers or potentiometers to provide even more granular control.

Configuration of Dip Switches

Setting Up Dip Switches

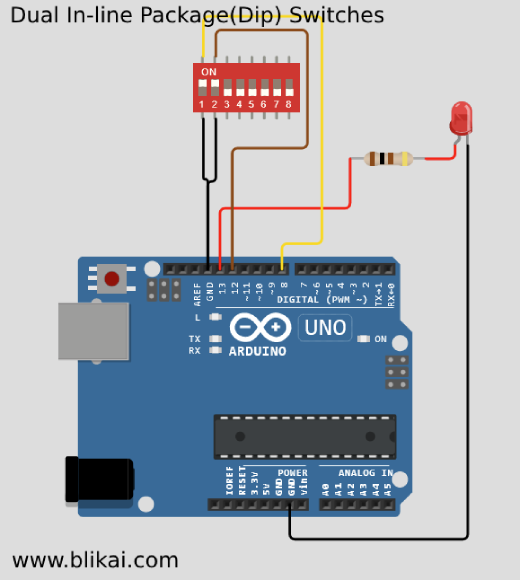

Identifying the specific settings needed for your device is the first step in configuring a dip switch. This usually entails understanding how each switch operates by studying the documentation or equipment handbook. Typically, dip switches are placed in a single row. Additionally, each switch has a “on” and “off” setting. Typically, the “on” position is shown. Usually, the switch has a label or notch. To modify the dip switches, a tiny tool like a screwdriver or pencil could be required. Turn each switch carefully to the correct position in accordance with the given configuration instructions to shift the switches. Verifying that every switch is securely positioned aids in preventing inadvertent adjustments or incorrect setups.

Reading Switch Positions

It’s easy to read the dip switch positions, although it does take careful attention to detail. There are two positions on each switch: “off” (0) and “on” (1). Typically, the switch state is read from top to bottom or left to right. The dip switch packet’s orientation determines this. Binary numbers are used by certain devices to represent switch positions. In this case, every switch stands for a binary number. For instance, if you have an eight-switch dip package, the positions could represent a byte in binary form, allowing for a range of 0 to 255 in decimal. Accurately reading and recording the positions of each switch ensures that you can replicate or modify the configuration as needed.

Step-by-Step Guide to Using Dip Switches

Tools Required

To configure dip switches, you will need a few basic tools:

– Small screwdriver: A flathead or Phillips screwdriver, depending on the type of dip switch, to flip the switches.

– Stylus or tweezers: Useful for precise adjustments in tight spaces.

– Magnifying glass: Helps in reading the small labels and positions on the dip switches.

– Flashlight: Ensures you have adequate lighting to see the switch positions clearly.

Safety Precautions

Before working with dip switches, follow these safety precautions:

– Power Off: Make sure the device is turned off and unplugged to prevent electric shock or unintended damage.

– Static Electricity: To release static electricity, touch a grounded metal object or wear an antistatic wristband. Electronic parts may be harmed by this.

– Clean Workspace: To keep dust and debris out of the equipment, work in a dry, clean atmosphere.

– Handle with Care: To prevent breaking the switch or the device, please turn the switch carefully.

Detailed Configuration Process

1. Identifying Switch Positions

First, locate the dip switch package on your device. Please refer to the device manual or documentation to understand the operation of each switch. Dip switches are usually numbered. For precise configuration, switch positions are usually labelled ‘on’ and ‘off’. You need to know which position corresponds to the setting you want to change.

2. Adjusting Switch Settings

Using your small screwdriver or stylus, gently flip each switch to the desired position. Follow these steps:

– Position Confirmation: Double-check the current position of each switch. The “on” position is typically marked or indented.

– Flipping Switches: Carefully move the switch to the required position. For a slide switch, slide it to the “on” or “off” side. For a toggle switch, flip it up or down. Ensure that the switch is fully engaged in the new position.

– Repeat as Needed: Continue this process for all the switches you need to adjust according to your configuration requirements.

3. Verifying Settings

Make that the switch’s settings correspond to the intended configuration after setting it:

– Visual Inspection: If required, check that all of the switches are in the proper positions with a magnifying glass.

– Double-Check Documentation: To ensure accuracy, check the switch settings in your device handbook.

– Power On and Test: Reconnect the device to its power source and turn it on. Check that the device operates as expected with the new settings. If it doesn’t, power off the device and recheck the switch positions.

Example Configuration Process

Suppose you are configuring the baud rate on a serial communication device with a four-switch dip package:

- Identify Positions: A table with the baud rate settings can be found in the device documentation. Suppose you wish to change the switches 1 and 3 to “off” and switches 2 and 4 to “on” by setting the baud rate to 19200.

- Adjust Switches: Switches 2 and 4 can be turned to the “on” position and switches 1 and 3 to the “off” position with a screwdriver.

- Verify Settings: Verify that each switch is in the proper position by checking it. To make sure, consult the handbook.

- Test: Turn the gadget on and make sure the desired baud rate is being communicated at.

You can effectively configure and alter your electronic gadgets with dip switches if you take the necessary safety precautions. This enables the equipment to function in accordance with your unique requirements.