I. Introduction

A. Definition

Manifold absolute pressure, or MAP, sensors are a pivotal part of contemporary machine operation systems. Its purpose is to gauge the machine input manifold’s pressure. After also, an electronic signal deduced from this pressure reading is transmitted to the engine control unit( ECU). Using this information, the ECU calculates the machine air viscosity and chooses the right energy injection and ignition timing.

B. Importance

A crucial element in maximizing machine performance is the Manifold absolute pressure sensor. The Manifold absolute pressure sensor helps the ECU to acclimatize the air- energy rate, energy injection, and ignition timing grounded on machine operating circumstances by giving real- time data on the input multifarious pressure. This optimization lowers exhaust adulterants, boosts energy effectiveness, and enhances machine performance. To put it simply, the Manifold absolute pressure sensor is essential to icing that the machine operates easily and effectively in every driving circumstance.

II. Principle of Operation

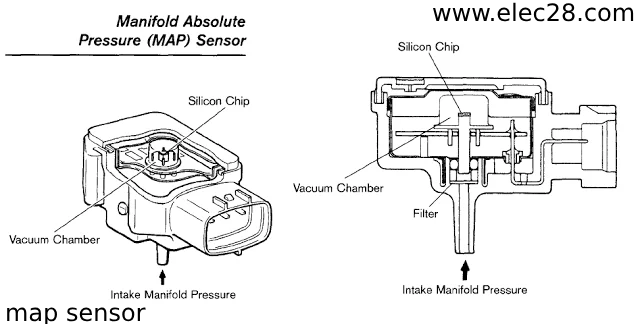

A. Explanation of pressure sensing element

A silicon-based pressure sensor is commonly used by the Manifold absolute pressure sensor. In reaction to variations in inlet manifold pressure, this component is intended to deform. The sensitive element deflects in response to variations in pressure, which alters electrical resistance accordingly. After measuring the resistance change, the sensor outputs a voltage signal.

B. Conversion of pressure to electrical signal

The engine control unit (ECU) receives the electrical signal that the Manifold absolute pressure sensor produced after the pressure was translated into one. The engine air density, fuel injection, and ignition timing are then calculated by the ECU using this data. The Manifold absolute pressure sensor provides vital information for optimal engine performance, functioning as the engine’s eyes and ears in a sense.

C. Compensation for atmospheric pressure changes

The Manifold absolute pressure sensor’s capability to acclimate for variations in atmospheric pressure is one of its crucial features. The sensor detects absolute pressure, thus in order to cipher machine cargo precisely, it must regard for differences in ambient pressure. In order to negotiate this, the ECU makes use of redundant sensors, like an atmospheric pressure sensor, to supply the reference needed to acclimate for variations in air pressure. This guarantees that the machine runs easily no matter what the outside air conditions are.

III. Role of Manifold absolute pressure Sensors in Engine Performance

A. Optimization of air-fuel ratio

Optimizing the machine’s air- energy rate is one of the Manifold absolute pressure sensor’s primary duties. The Manifold absolute pressure sensor gives the engine control unit( ECU) real- time data on the input multifarious pressure, which it uses to calculate the machine air viscosity. The ECU can modify the quantum of energy injected into the machine to maintain the ideal air- energy rate during combustion by using this information. This guarantees optimal machine performance and minimizes energy consumption while producing optimum power.

B. Adjustment of fuel injection and ignition timing

Apart from enhancing the air- energy rate, the Manifold absolute pressure sensor is essential for energy injection and timing machine ignition. The machine cargo and operating conditions can be caught on by the ECU using the input multifarious pressure measures that are supplied by the Manifold absolute pressure sensor. The ECU can regulate energy injection and ignition timing grounded on this information to guarantee the stylish possible machine performance and effectiveness. This enhances overall drivability, gearbox, and throttle responsiveness.

C. Impact on engine performance, fuel efficiency, and emissions

The Manifold absolute pressure sensor’s data is crucial for preserving the best possible engine performance, fuel efficiency, and emissions. The ECU can make real-time adjustments to engine running because to the Manifold absolute pressure sensor’s continual monitoring of intake manifold pressure. This maximizes performance while reducing fuel consumption and pollutants, ensuring smooth and economical engine functioning under all driving circumstances. Essentially, the Manifold absolute pressure sensor is a vital part of contemporary engine management systems, assisting in making sure that cars fulfill strict emissions regulations while providing the efficiency and performance that drivers require.

IV. Common Manifold absolute pressure Sensor Problems and Solutions

A. Contamination or damage to sensing element

Contamination or damage to the sensor element is a common issue with Manifold absolute pressure sensors. The capacity of the seeing element to precisely cover the inlet multifarious pressure may be hampered over time by impurity from dirt, oil painting, or other debris. likewise, physical trauma or extreme vibration may harm the sensing element, leading to incorrect pressure measures. In some situations, it might be necessary to replace or clean the Manifold absolute pressure sensor in order to get it working again.

B. Electrical issues: wiring harness, connector corrosion

Electrical issues with Manifold absolute pressure sensors could also include erosion in the draw or string. deceiving readings or intermittent signal loss might be caused by wiring issues, similar as weak connections or old lines. Similarly, the signal between the engine control unit( ECU) and the Manifold absolute pressure sensor may be affected by oxidation or erosion of electrical connections. To restore a correct electrical connection under similar circumstances, the wiring may need to be fixed or replaced, and the connectors may need to be gutted or changed.

C. Diagnosis using scan tool

When a suspected Manifold absolute pressure sensor issue arises, the output voltage of the sensor is often read using a scan tool for diagnostics. With the use of the scan tool, the technician may view the sensor’s output in real time and compare it to the manufacturer’s requirements. To identify the root of the issue, more diagnostics could be necessary if the sensor output voltage is outside of the typical range. The accompanying fault codes that are kept in the memory of the engine control unit (ECU) can also be checked with the scan tool, and doing so can yield important diagnostic data.

D. Replacement procedure

In the event that it is found that the Manifold absolute pressure sensor needs to be replaced due to malfunction, the process is rather straightforward. The transducer is usually fastened in place with a few bolts or screws and is situated on or close to the inlet manifold. The sensor can be carefully removed from the manifold after the electrical plug has been taken out and all screws have been detached. After that, the replacement transducer can be placed backwards, being careful to line and clean the sealing surfaces. To reset any error codes that may have been saved and to recalibrate the new sensor, it could be essential to reset the engine control unit (ECU) after installation.

V. Conclusion: Maintaining Manifold absolute pressure Sensor Health

You can guarantee that your machine operates easily and efficiently in all driving situations by keeping your Manifold absolute pressure sensor in good condition. The engine control unit( ECU) can acclimate the air- energy rate, energy injection, and ignition timing in real time to optimize performance, energy frugality, and emigrations when the Manifold absolute pressure sensor is performing duly. This ensures that your auto will keep performing at its peak for numerous times to come. It also helps to lower energy consumption and adulterants while perfecting machine performance and drivability.